high quality slurry pump interchangeable spare parts manufacturers

Latest articles

Slurry Pump

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read More- Pumping media where abrasive particles are present

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreLess downtime

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreAre the pump discharge components suitable for the slurry being pumped?

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreSlurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreSlurry pump vs mud pump

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

high quality slurry pump interchangeable spare parts manufacturers...

high quality slurry pump interchangeable spare parts manufacturers 【high quality slurry pump interchangeable spare parts manufacturers】

Read More

Popular articles

- Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

- The company uses advanced computer assistant engineering software to design products and technology, which makes our

- What is a slurry?

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

Latest articles

-

Light-duty Slurry Pump

-

High head (i.e. the height to which the pump can move the liquid)

-

Slurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

-

Using rubber as a wear lining material means

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

Slurry pump design

Links

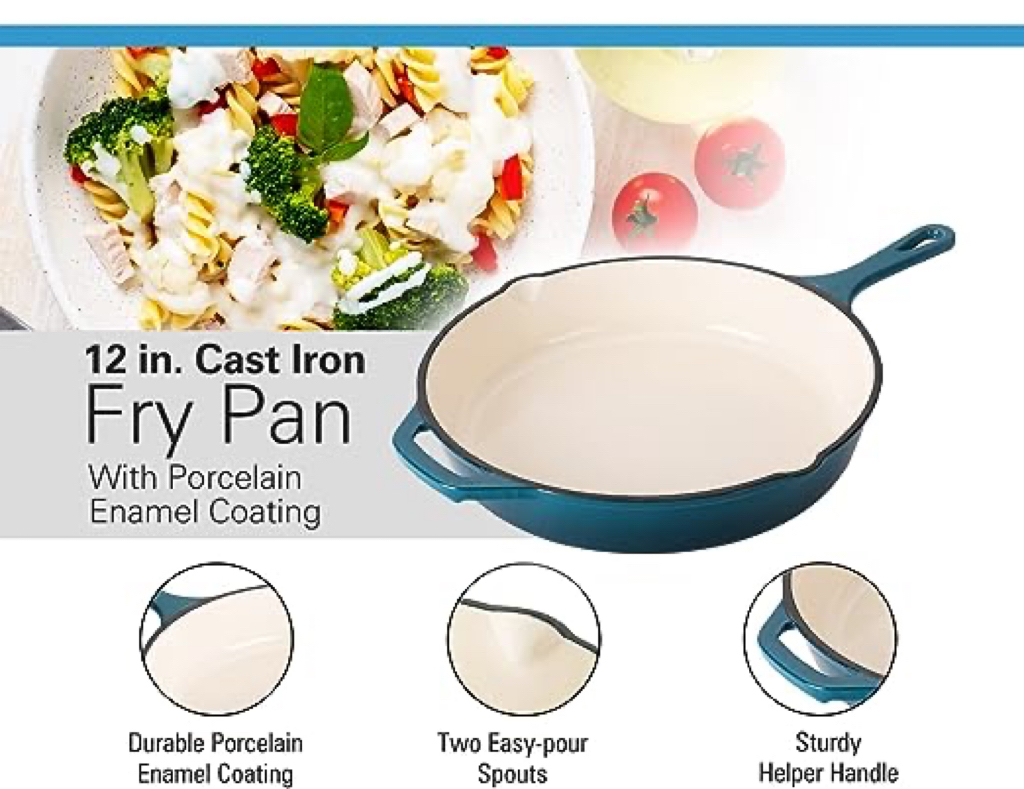

Ultimately, the type of frying pan you choose will depend on your individual cooking style, needs, and preferences. No matter which type you choose, a quality frying pan is an essential kitchen tool that will provide you with years of cooking enjoyment.

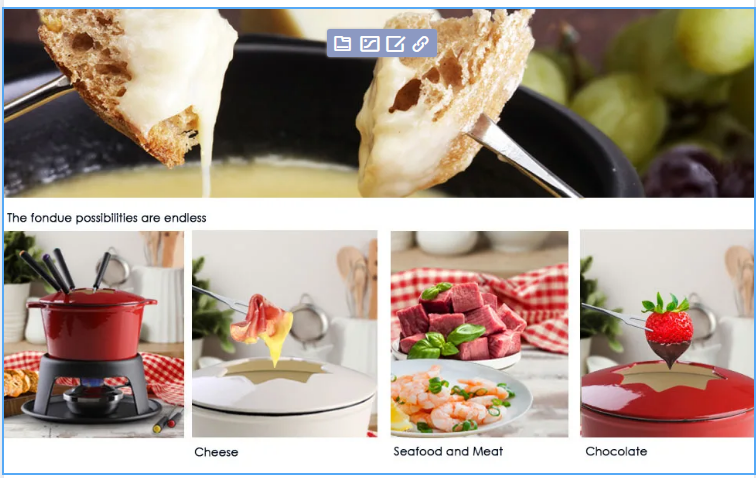

- **Buying an Enamel Potjie Pot

In addition to restoring enameled cast iron cookware, maintenance is also crucial. When using enamel potjie pot for sale, avoid using metal utensils or sharp cooking tools to avoid scratching the enamel surface. Also, avoid suddenly cooling enamel cast iron pots for sale.at high temperatures to avoid thermal shock cracks. Regular cleaning and maintenance of enamel cookware is also key to maintaining its appearance and performance.

Aesthetic Appeal and Presentation:

A cast iron cookware set is a great investment for anyone looking to build a versatile cookware collection. Cookware Sets often include a variety of pots, pans, and frying pans, providing options for different cooking techniques and recipes.

3. Non-Stick Frying Pans

Whereas skillets are commonly made from cast iron or stainless steel, giving it its rugged and robust nature. You’ll also be hard-pressed to find a “cast iron frypan”, but you’ll often find “cast iron skillets”. Even though stainless steel is one of the common materials used to make skillets, cast iron is the more popular option.

Dutch Oven Manufacturers

porcelain cookware set. Its smooth surface makes it easy to wipe clean with a damp cloth or sponge, and most porcelain cookware sets are also dishwasher safe. This means that you can spend less time cleaning up after cooking and more time enjoying your delicious meals.

How to clean: For burned stains, boil 2 cups water and 1 tablespoon distilled white vinegar in the pan for 20 minutes, then scrub.

Characteristics Of Enamel Cookware

The home chef considering his or her options for cookware can be overwhelmed by the level of choice. It can be challenging to know which frypan is best suited to your needs without getting confused. Read on to discover what you need to consider before investing in your newest piece of cookware.

The ideal cookware size is a personal choice and a lifestyle choice. Smaller skillets and sauté pans are great for one- or two-person meals or quick bites (ex., breakfast scrambles or side dishes), while larger sizes are able to cook family-size portions or complete one-pan meals.

Regular seasoning with oil will help prevent rust and maintain a non-stick surface, while proper cleaning after each use will ensure that your grill pan stays in prime cooking condition Regular seasoning with oil will help prevent rust and maintain a non-stick surface, while proper cleaning after each use will ensure that your grill pan stays in prime cooking condition

Regular seasoning with oil will help prevent rust and maintain a non-stick surface, while proper cleaning after each use will ensure that your grill pan stays in prime cooking condition Regular seasoning with oil will help prevent rust and maintain a non-stick surface, while proper cleaning after each use will ensure that your grill pan stays in prime cooking condition cast iron square grill pan.

cast iron square grill pan. Whether you're searing a steak or simmering a sauce, cast iron provides the ideal environment for cooking Whether you're searing a steak or simmering a sauce, cast iron provides the ideal environment for cooking

Whether you're searing a steak or simmering a sauce, cast iron provides the ideal environment for cooking Whether you're searing a steak or simmering a sauce, cast iron provides the ideal environment for cooking cast iron cookware company. In addition, the heavy weight of cast iron helps to prevent scorching and burning, making it an excellent choice for beginners and experienced cooks alike.

cast iron cookware company. In addition, the heavy weight of cast iron helps to prevent scorching and burning, making it an excellent choice for beginners and experienced cooks alike.

Frying pans are usually made from various materials, including cast iron, stainless steel, aluminium, and copper. Each material has unique properties that make it suitable for specific types of cooking.

The enamel coating comes in a wide range of colors, allowing cooks to match their pan to their décor or add a pop of color to their cooking space The enamel coating comes in a wide range of colors, allowing cooks to match their pan to their décor or add a pop of color to their cooking space

The enamel coating comes in a wide range of colors, allowing cooks to match their pan to their décor or add a pop of color to their cooking space The enamel coating comes in a wide range of colors, allowing cooks to match their pan to their décor or add a pop of color to their cooking space enamel coated cast iron frying pan. These pans can easily go from stovetop to table, making them perfect for serving dishes straight from the pan.

enamel coated cast iron frying pan. These pans can easily go from stovetop to table, making them perfect for serving dishes straight from the pan. With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible

With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible iron skillets for sale. This feature is particularly beneficial for those who want to reduce their fat intake while enjoying delicious meals.

iron skillets for sale. This feature is particularly beneficial for those who want to reduce their fat intake while enjoying delicious meals.